Star Automation robots are compatible with Niigata IMMs through SPI 32-pin and 50-pin standardized robot-to-press interfacing. Older machines have a terminal strip that allows for direct wire compatibility.

Not sure if your machine is compatible? Our staff is on-call 24/7 for training, repair, and maintenance questions.

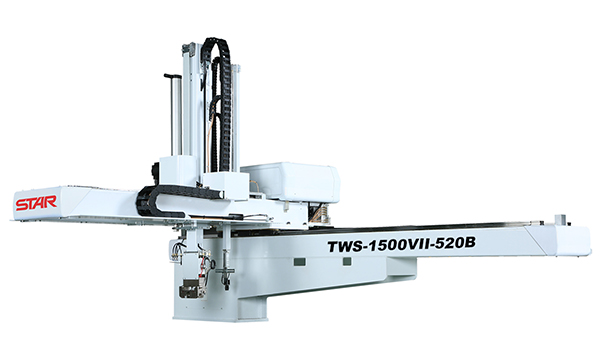

Servo Robots for Niigata Injection Molding Systems

Our servo robots remove plastic products from their injection mold. We have 13 servo robots with a variety of vertical stroke and weight capacities.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Sprue Pickers for Niigata IMMs

Swing-type sprue pickers remove excess plastic from the injection molding machines. We have three options with varying vertical stroke capacities that are all compatible with Niigata IMMs.

Conveyor Belt Systems for Niigata IMMs

Transport your finished goods from one place to another, reducing labor costs and making your production floor more efficient overall. We offer 8 types of conveyor belts.

All of our models have an adjustable height between 35 and 51 in. with a 900mm - 1300mm adjustable tilting angle. They have an AC120V single-phase power supply of 40 W that allows for a belt speed of 10 ft per minute. Each model includes a variable speed drive, indexing control, and a 32-foot power cord. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Pallet Changer Systems for Niigata IMMs

Move small plastic parts with a pallet changer from Star Automation. We offer three models that vary in loading weight and replacement speed.

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

End of Arm Tooling (E.O.A.T.) for Niigata IMMs

Star Automation specializes in end of arm tooling for Niigata injection molding machines. Whether you need tubing, suction components, or electronic attachments, we have you covered. Our massive variety of E.O.A.T. parts includes:

For more information or a free quote on automation robots for Niigata brand IMMs, contact Star Automation today.