LS Mtron, a spinoff of South Korea’s LG and LG Group, is a leading company in the areas of industrial electricity and electronics, materials, machinery, components, and energy. LS Mtron has been creating IMMs as early as the 1960s. They now make both electric and hybrid IMMs that are used in industries like automotive, packaging, medical, and home goods.

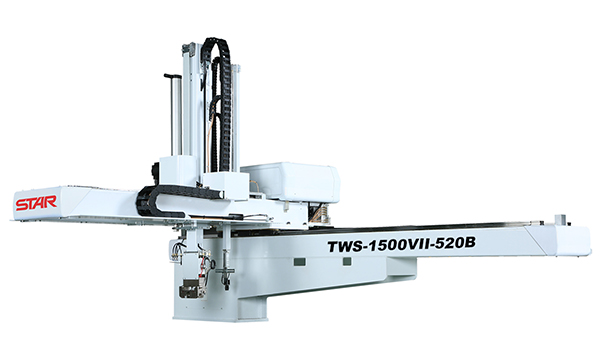

Star Automation uses the widely utilized SPI 32-pin and 50-pin interfaces to provide smooth interaction with LS Mtron IMMs. Small to extra-large take-out robots, high-speed machines made for thin-wall packaging, high-duty models, vertical machines, insert molding machines, 2-shot machines, and liquid injection molding machines are just a few of the molding equipment we offer to meet different needs.

If you have any questions, need training, maintenance, or anything in between, please reach out. We would be more than happy to assist!

Servo Robots for LS Mtron Injection Molding Systems

If you need servo motor-driven take-out robots tailored for LS Mtron IMMs, Star Automation is the leading supplier. These robots offer seamless extraction of the hardened plastic product from the mold, thanks to their advanced servo motor technology.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Sprue Pickers for LS Mtron IMMs

Enjoy the simplicity and safety of Star Automation's swing-type sprue pickers, designed with user-friendliness in mind. These compact and intuitive pickers feature a mold change memory capable of storing up to 15 molds, resulting in increased productivity. With the XQ.V series, assembly is made easier by eliminating unnecessary wiring and piping. Vertical stroke lengths vary by model, spanning from 450 mm to 800 mm, and changing the release side is now faster and more convenient than ever before.

Conveyor Belt Systems for LS Mtron IMMs

Our models boast adjustable heights ranging from 35 to 51 inches, coupled with an adjustable tilting angle spanning from 900mm to 1300mm. These models are powered by a single-phase AC120V power supply, consuming 40 W, which enables a belt speed of 10 feet per minute. Noteworthy features include a variable speed drive, indexing control, and a 32-foot power cord. To cater to unique requirements, a range of additional options are also provided. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Pallet Changer Systems for LS Mtron IMMs

Optimize your productivity by utilizing pallet changers, which efficiently transport raw or finished plastic parts, effectively reducing the time spent on loading and unloading operations. Our models feature precise numerical control systems, ensuring accurate performance. Choose from our selection of three LS Mtron-compatible models, each offering different speed and weight capacities, empowering you to meet your specific requirements.

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

End of Arm Tooling (E.O.A.T.) for LS Mtron IMMs

We offer a wide array of E.O.A.T. attachments for LS Mtron IMMs for a variety of applications. Whether you’re looking for cutting tools, gripping or suction components, Star Automation is here to help.

Our massive variety of E.O.A.T. parts includes:

For more information or a free quote on automation robots for LS Mtron brand IMMs, contact Star Automation today.