Yizumi-HPM is a reputable company that produces top-notch hybrid injection molding machines, as well as hot and cold chamber die casting machines ranging. With a history dating back to 1931, HPM has been a reliable supplier of injection molding machinery and support services to the plastic industry. They have numerous Injection Molding and Die Casting Machines currently operating across North America.

Star Automation can seamlessly integrate with HPM machines using the standardized robot-to-press interface of SPI 32-pin and 50-pin connectors. We provide a range of molding machines, including micro to large-sized options, high-speed machines for thin-wall packaging, high-duty models, vertical machines, insert molding machines, 2-shot machines, and liquid injection molding machines.

If you have any questions, need training, maintenance, or anything in between, please reach out. We would be more than happy to assist!

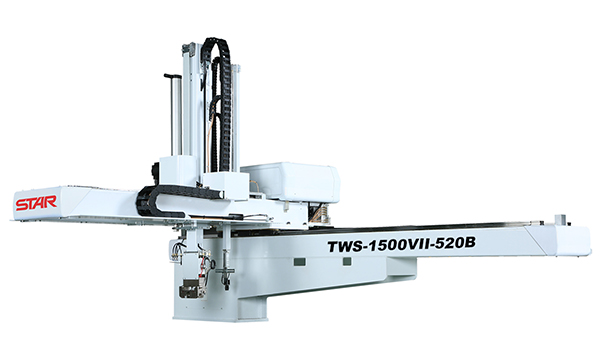

Servo Robots for HPM Injection Molding Systems

Star Automation is a leading provider of servo motor-driven take-out robots designed for HPM IMMs. These robots effectively and automatically remove the finished plastic product from the mold after it has hardened.

Servo robots are compatible with HPM injection press ranges between 20-4 and 2500-5000 tons. See the chart below for compatibility or contact Star Automation for help.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Sprue Pickers for HPM IMMs

Star Automation offers user-friendly and secure swing-type sprue pickers that are known for their ease of use. These pickers are designed to be compact and intuitive, and they have the capability to store up to 15 molds in the mold change memory, resulting in improved productivity. With the XQ.V series, assembly is simplified by eliminating unnecessary wiring and piping. The vertical stroke lengths vary across different models, ranging from 450 mm to 800 mm, and changing the release side has never been quicker or simpler.

Conveyor Belt Systems for HPM IMMs

Our range of models offers adjustable heights ranging from 35 to 51 inches, coupled with an adjustable tilting angle of 900mm to 1300mm. Powered by an AC120V single-phase power supply, these models operate at 40 W, enabling a belt speed of 10 feet per minute. Each model is equipped with a variable speed drive, indexing control, and a 32-foot power cord. Customizable options are also available to suit specific requirements. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Pallet Changer Systems for HPM IMMs

Pallet changers play a crucial role in optimizing the transportation of raw or finished plastic parts, significantly reducing the loading and unloading time. Our models are equipped with numerical control, ensuring enhanced precision and accuracy. We provide three HPM -compatible models, each offering different speed and weight capacities to cater to various requirements.

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

End of Arm Tooling (E.O.A.T.) for HPM IMMs

Star Automation produces grip, suction, quick change and cutting EOAT components that are safe, effective and reliable. Build your own tooling to cut costs with Star Automation.

Our massive variety of E.O.A.T. parts includes:

For more information or a free quote on automation robots for HPM brand IMMs, contact Star Automation today.