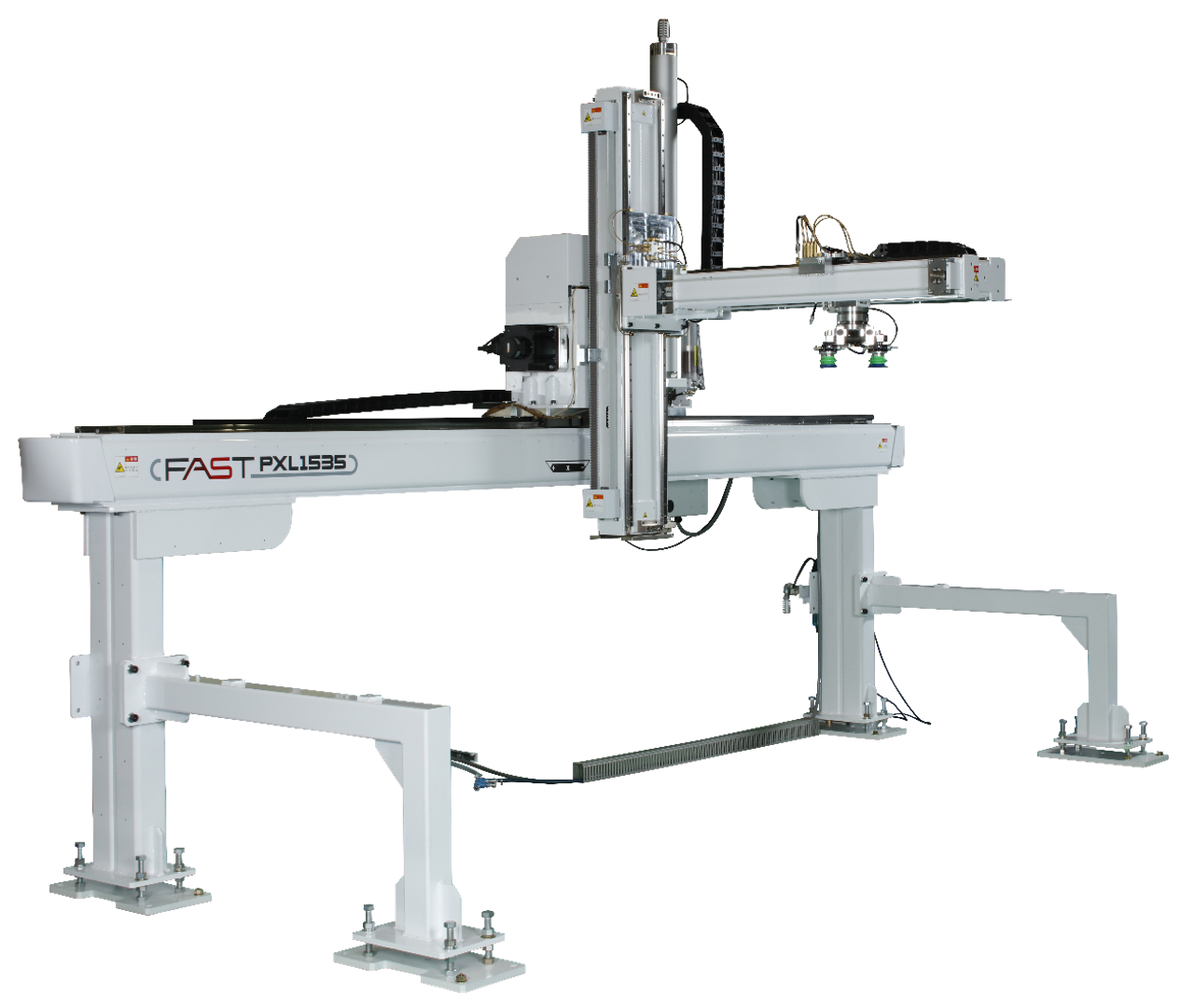

PXL-1535 Robot Palletizer

PXL-1535

| Vertical Stroke (mm) |

Range of IMM (Ton): |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Download Model PDF |

|---|---|---|---|---|

|

|

Technical Specs:

Star Automation’s PXL-1535 robotic palletizer is a multi-palletizer designed for low overall height while providing efficient multi-tier stacking. It is engineered to reduce manual labor, optimize plant floor space, and deliver consistent throughput. With the ability to process up to 10 boxes per minute, the PXL-1535 is ideal for applications in industries such as food, beverages, pharmaceuticals, and cosmetics.

The PXL-1535 is built to handle multi-tier palletizing while maintaining the same stacking height as the PXW-1535—yet its overall machine height is 1114 mm lower. It also automatically corrects package misalignment that occurs with multi-tier stacking during pallet transfers, ensuring accuracy and stability.

Like all Star Automation palletizers, the PXL-1535 comes with a customized implementation plan. Our engineers provide installation, operator training, and ongoing service to ensure seamless integration and long-term performance. Standard and optional features for the PXL-1535 are listed below:

|

Normal Air Pressure |

0.5 MPa |

|

Max. Payload |

35 kg |

|

Vertical Axis Stroke (OP) |

1500 mm |

|

Crosswise Axis Stroke (OP) |

1000 mm |

|

Traverse Axis Stroke (OP) |

3500 mm |

|

Swivel Axis (OP) |

±160° |

|

Power Supply |

200–220 VAC ±10% 50/60 Hz |

|

Power Supply Equipment Capacity |

8.9 kVA |

|

Max. Power Consumption |

4.5 kW |

|

Breaker Capacity |

30 A |

|

Main Unit Air Consumption |

103 L/min |

|

Main Unit Weight |

1445 kg |

|

Controller |

STEC-520PB Controller |

Standard Features

- Multi-palletizer design for low-height installations

- Capable of multi-tier stacking with reduced overall height

- Automatically corrects misalignment during pallet transfers

- High payload capacity up to 35 kg

- Throughput of 10 boxes per minute

- Space-saving design for efficient floor layouts

Optional Features

- Pallet feeder for continuous operation

- Depalletizing function

- Robot hand suction system

- Servo hand option for precise handling